Decorative-Concrete-Supply

Gorilla Coatings Concrete Crack and Spall Repair

Gorilla Coatings Concrete Crack and Spall Repair

Couldn't load pickup availability

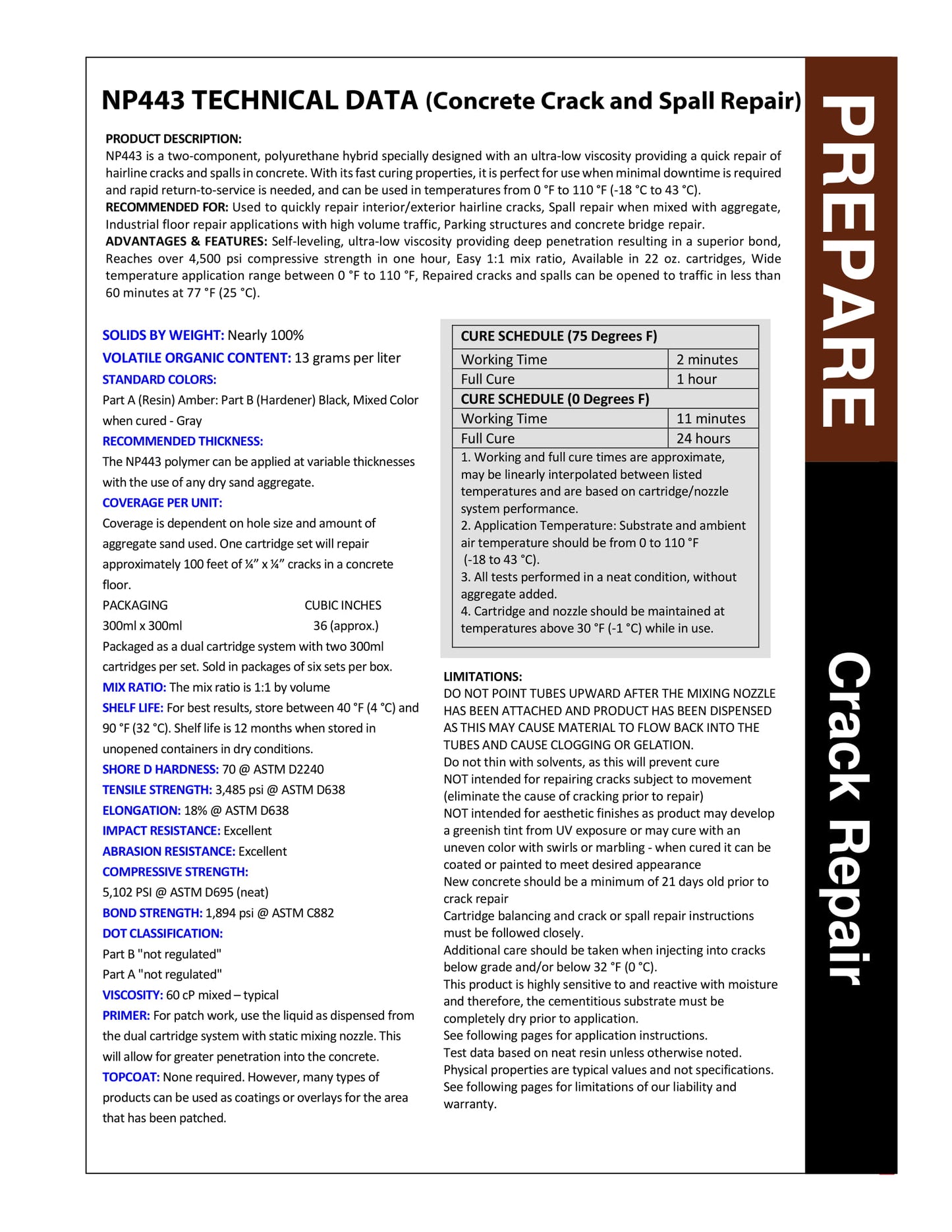

NP443 is a two-component, polyurethane hybrid specially designed with an ultra-low viscosity providing a quick repair of hairline cracks and spalls in concrete. With its fast curing properties, it is perfect for use when minimal downtime is required and rapid return-to-service is needed, and can be used in temperatures from 0 °F to 110 °F (-18 °C to 43 °C).

RECOMMENDED FOR: Used to quickly repair interior/exterior hairline cracks, Spall repair when mixed with aggregate, Industrial floor repair applications with high volume traffic, Parking structures and concrete bridge repair.

ADVANTAGES & FEATURES: Self-leveling, ultra-low viscosity providing deep penetration resulting in a superior bond, Reaches over 4,500 psi compressive strength in one hour, Easy 1:1 mix ratio, Available in 22 oz. cartridges, Wide temperature application range between 0 °F to 110 °F, Repaired cracks and spalls can be opened to traffic in less than 60 minutes at 77 °F (25 °C).

SOLIDS BY WEIGHT: Nearly 100%

VOLATILE ORGANIC CONTENT: 13 grams per liter.

STANDARD COLORS: Part A (Resin) Amber: Part B (Hardener) Black, Mixed Color when cured - Gray

RECOMMENDED THICKNESS: The NP443 polymer can be applied at variable thicknesses with the use of any dry sand aggregate.

COVERAGE PER UNIT: Coverage is dependent on hole size and amount of aggregate sand used. One cartridge set will repair approximately 100 feet of ¼” x ¼” cracks in a concrete floor.

PACKAGING (CUBIC INCHES): 300ml x 300ml (36 (approx.) )

Packaged as a dual cartridge system with two 300ml cartridges per set. Sold in packages of six sets per box.

MIX RATIO: The mix ratio is 1:1 by volume.

SHELF LIFE: For best results, store between 40 °F (4 °C) and 90 °F (32 °C). Shelf life is 12 months when stored in unopened containers in dry conditions.

SHORE D HARDNESS: 70 @ ASTM D2240

TENSILE STRENGTH: 3,485 psi @ ASTM D638

ELONGATION: 18% @ ASTM D638

IMPACT RESISTANCE: Excellent

ABRASION RESISTANCE: Excellent

COMPRESSIVE STRENGTH: 5,102 PSI @ ASTM D695 (neat)

BOND STRENGTH: 1,894 psi @ ASTM C882

DOT CLASSIFICATION: Part B "not regulated" Part A "not regulated"

VISCOSITY: 60 cP mixed – typical

PRIMER: For patch work, use the liquid as dispensed from the dual cartridge system with static mixing nozzle. This will allow for greater penetration into the concrete.

TOPCOAT: None required. However, many types of products can be used as coatings or overlays for the area that has been patched.

For Safety Data Sheet, Please Download SDS

For Technical Data Sheet, Please Download TDS

Share